A 21st Century Solution for Modern Boating

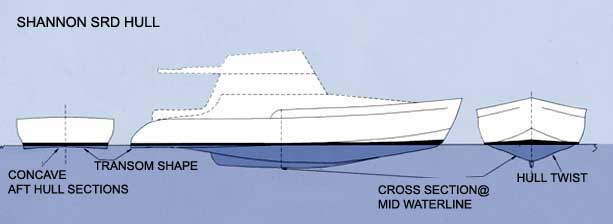

The SRD hull shape combines the best features of semi-displacement and deep vee hull shapes and eliminates their deficiencies. The deep vee sections of the bow on the SRD hull provide a fine entry and prevent the boat from pounding in a seaway. A twist in the mid-section of the hull lines creates a constant hydrodynamic flow to direct lift to the pronounced concave aft sections. The lift of these concave aft sections allows the SRD to reach speeds of modified deep vee hulls. In addition to lift, the laminar flow travelling along the hull creates significant form stability which prevents the rolling motion that occurs with displacement and semi-displacement hulls. The SRD hull has rock solid stability without stabilizers and is easy to maneuver at speeds from 2 to 30 knots. The hydrodynamic lift of the SRD hull reduces wetted surface like a deep vee but requires only half as much horsepower to achieve this lift. These unique features of the SRD qualified for two U.S. patents*.

Based on independent testing, the SRD hull, with a single engine or twin engines, is the most fuel efficient powerboat on the market at speeds over 10 knots/12 mph. While the SRD hull can easily reach speeds of 25 knots/30 mph or greater depending on engine horsepower, the hull provides exceptional fuel economy in the 10 knot /12 mph to 18 knot /20 mph speed range. At 10 knots, the SRD obtains almost 2 miles per gallon, or the same fuel burn found on a full displacement trawler at top speed. Traveling at 15 knots, the SRD provides over 1.6 miles per gallon, whereas a modified vee planing hull struggles to provide 1 mile to the gallon at the same speed. The fuel efficiency of the SRD hull translates into 60% less fuel burned, increased range and a significant reduction in pollution.

SRD Design and Testing Background

After successfully designing and obtaining a U.S. patent in 2000 for a revolutionary sailboat hull that could sail well without a deep keel – a problem that had been confounding sailors for centuries, Walter Schulz set out to come up with a Twenty-First Century solution to the powerboat dilemma of fuel burn, seaworthiness, speed, range and shallow draft. Walt had designed Shannon’s modified vee powerboats since 1985, and was intimately familiar with all the drawbacks of all the existent hull shapes. Using sophisticated CAD software and hydrodynamic flow knowledge obtained during an eight year sailboat patent effort, he developed a new powerboat hull shape that fully utilizes the opportunies of blended shapes that could be obtained only using fiberglass molded construction. In 2003, the first 38 foot SRD (Schulz Reverse Deadrise) prototype hull with twin engines was launched and sea trialed by Walt over 1200 miles from Maine to the Bahamas in every conceivable wind and sea condition. The SRD performed beyond expectations. The following year SRD hull #2 was built with some minor modifications and a single engine to further test the hull shape in all ocean conditions. Two more 38’ protoypes were built over the next few years to test engine size and propulsion systems, including surface piercing propellers and hybrid drives. Everyone who sea-trialed the 38 SRD from marine magazine writers to professional captains to experienced boaters raved about the fuel economy and seaworthiness of the SRD. Walt filed for a patent on the hull design and the U.S. Patent Office awarded the second patent* in 2006. The combination of waiting to see the development of new engine pod drives, which are ideal for the SRD hull, and world economic conditions, slowed the introduction of the new SRD 40, 48 and 58 that incorporates over seven years of design and testing. The combination of the SRD technology and Shannon’s 35 year international reputation for quality makes the SRD a totally proven solution for twenty-first century boating realities.

*US Patent# 63250009

*Us Patent #7,225,752

The available hull designs found on most powerboats and trawlers today reached their peak of development in the mid-twentieth century when people were crossing the Atlantic in propeller-driven airplanes and fuel cost 20 cents a gallon. While fiberglass boat construction technology has considerably advanced over the period, underwater hull shape has remained virtually stagnant. There are four basic hull designs used by the yacht industry today: full displacement found on trawlers; semi-displacement found on lobster boats and some trawlers; planing hulls found on most powerboats; and multi- hull powerboats. . These hull designs were all being used in the 1950’s when the most popular boat-building materials were wood or steel, and fiberglass was just becoming accepted.

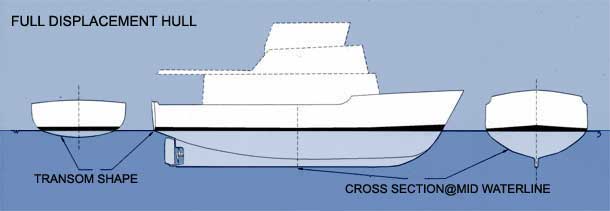

Full displacement hull designs are found on trawler yachts, sailboats and big cruise ships. The speed of these hulls is physically constrained by length of waterline. A trawler with a waterline length of 40 feet can travel at a maximum speed of 8 knots (9 MPH), determined by the formula of maximum speed of a displacement hull is the square root of the waterline x 1.3. At 7 knots or less, a trawler can achieve excellent fuel efficiency much like a sailboat under power. Another concern for displacement hulls, besides speed, is the fact that round bilged displacement hulls roll terribly in a seaway despite the use of heavy hull ballast unless they use some form of stabilizing equipment. However, these stabilizers are actually fins that protrude from the hull and cause drag which slows down the vessel. Even cruise ships, which acquire stability with their massive weight, have stabilizers. Active vane stabilizers are expensive and very complicated, especially on smaller vessels of less than 100 feet in length. Compounding the potential breakdown of stabilizers is the fact that many trawlers are designed with super structures that are too high. (They are designed this way to create extra interior accommodations). This high center of gravity accentuates the nauseating rolling tendency of trawlers.

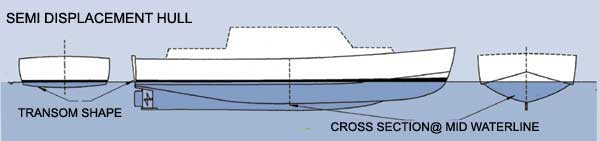

Semi-displacement hulls have been common on steel commercial fishing vessels for the past 50 years. Unlike full displacement vessels, semi displacement hulls can slightly exceed waterline length constraints, and achieve maximum speeds equal to about 1.6 times the length of the waterline, or 10 knots/12 mph for a semi-displacement hull with a waterline length of 40 feet. The flat hull sections aft on a semi-displacement hull provide some hydrodynamic lift. The primary reason for the development of this hull shape was the ability of the hull to run at acceptable speeds whether empty or fully loaded. The flat aft sections offer resistance as extra weight tries to cause the hull to sink, as with a displacement hull. This ability to add extra loading weight is very important for commercial fishing boats. A fishing boat has to run out to the fishing grounds relatively empty at a higher speed and return with its hold fully loaded at displacement speeds. But, since the semi-displacement hull has round hull sections forward of the flat aft sections, it tends to roll side-to-side in waves like a displacement hull. Practically every commercial fishing vessel also relies on stabilizers or mechanical paravanes to prevent rolling in a seaway. Semi-displacement hulls might make sense for fishing boats, but the problems of low speed, fuel inefficiency and motion makes this hull shape generally unsuitable for pleasure yachts.

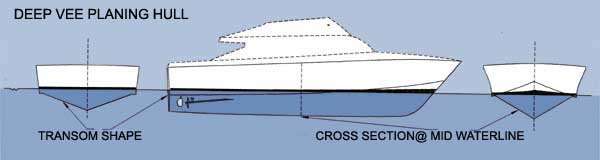

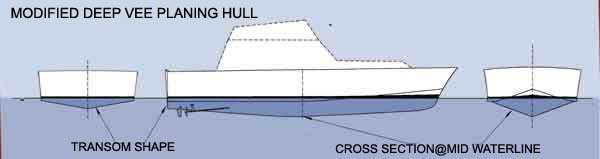

Planing hulls achieve high speeds by using a hydrodynamic hull shape to lift the boat out of the water. Planing hulls are called deep vee or modified deep vee with the vee shape along the keel less pronounced. Once a planing boat reaches the speed of approximately 12 knots/14 mph the hull actually lifts up – gets up on plane – to reduce its underwater hull surface and provide more speed. The development of smaller engines (both inboard and outboard) with greater horsepower in the 1950’s established the planing hull as the dominant hull shape for yachts. The major problem with planing hulls is that in order to achieve higher speed more engine horsepower is necessary, which translates into higher fuel costs and more exhaust pollution. Another problem with planing hulls (deep or modified) is that they are terribly fuel inefficient and difficult to handle during storms when forced to travel below planing speeds. Even in moderate seas it is difficult to travel at speeds in excess of 25 knots/29 mph in a planning hull without punishing people and the boat.

Multi-hulls come in two configurations: catamarans with two hulls; and trimarans with three hulls. Ultra light weight multi hull sailboats are capable of reaching very high speeds under sail. The problem with multi-hulls is weight sensitivity. In order to provide even modest comfort and amenities, multi-hulls drastically sacrifice any speed or efficiency advantage. The excessive beam creates difficulty for dockage and routine hauling in many marinas. A cruising power cat or tri travels at about the same speed and efficiency as a semi-displacement monohull . The “raft-like motion” in a seaway has also inhibited the popularity of power multi-hulls.